As a basic industrial material, screws underpin our society. The wide variety of products handled by Yahata Neji amounts to approximately 400,000 items. Our screws are used by a wide variety of customers, including automobiles, electronics, machinery, construction, and home improvement center retailers nationwide. We supply a wide range of screws from major manufacturers to general users. Throughout its 70-year history, Yahata Neji has challenged itself with the concept of “delivering high-quality products to customers without fail.”We manufacture a wide variety of products at our Japanese and overseas factories, as well as at over 800 cooperating factories in Japan and overseas. Yahata Neji has built a thorough streamlining “improvement of manufacturing technology”, “global quality control system”, and “advanced logistics system utilizing IT and mechatronics”. We collectively called this “The smooth flow of goods and information” and have evolved it. Yahata Neji’s corporate mission is to “deliver peace of mind to our customers” as a company that can contribute to the development of our business partners and society, based on our corporate philosophy of “SanPouZen no Kokoro (heart of three way virtues)”.

Yahata Neji has a history of challenges to evolve “the smooth flow of goods and information”.

QUALITY

“The smooth flow of goods and information” Quality control of manufacturing and logistics

Quality control using our own IT technology

The quality that Yahata Neji considers is “product quality” and “distribution quality”. For customers, manufacturing realizes not only making high-quality products, but also not having a shortages of even one screw. Shipment quality is also an important indicator for supplying reliable products at the right time, in the right amount, and in the most suitable packaging. In order to realize this advanced product supply system at low cost, we have developed and utilized our own IT and mechatronics technology to promote rationalization. We are improving our accuracy day by day.

Yahata Neji has been aiming for “QCDA*1”, that is, “high-quality products”, “realization of low-cost production and distribution”, “reliable same-day delivery”, and “advanced product classification”.

One example of this is the Yahata Flow System, a company-wide integrated production system developed in-house that combines computers and mechatronics. At the same time, we have created an ideal distribution environment in which customers can quickly obtain what they want, when they want it, by constructing our in-house developed ordering system “YES”.

Managing all the warehousing, management, and shipping of 150,000 types of products using the above-mentioned “QCDA” ( (1) prevention of incorrect product shipment, and (2) lowering cost by reducing human work, (3) same-day shipping, and (4) from single piece to pallet unit) allows us to deliver in a way that suits the customers.

Yahata Neji’s advanced logistics system is evolving day by day.

※1 Quality,Cost,Delivery,Assortment

Our own system development that continues to evolve.

— Received the “Minister of Economy, Trade and Industry Award” as the Small and Medium Enterprise IT Management Power Award —

Since the start of computerization in 1979

1982 – Operation of an online system with customers.

1983 – Operation of the second system aimed at real-time processing,

1987 – Operation of the third integrated system

2001 – Development of intelligent computer system “YaCS-EDI” started,

2007 – Company-wide integrated system ” YaCS-EDI” started full-scale operation.

2018 – The self-developed ordering system “YES” started operation.

From the beginning of computerization to the present, we have developed our own

easy-to-use systems. Despite repeated obstacles, we have overcome these challenges.

The accumulation of this know-how has led to the evolution of Yahata Neji.

In 2008, Yahata Neji’s IT efforts were recognized, and we received the “Minister of Economy, Trade and Industry Award“, the 1st Small and Medium Enterprise IT Management Grand Prize sponsored by the Ministry of Economy, Trade and Industry.

Sophistication of the quality control system based on the idea of ”SoKyakuJin (thinking of customers)”.

Yahata Neji expresses customer orientation with the word “SoKyakuJin (thinking of customers)”. To supply products that customers want and to do work that can meet their need. To that end, we have established an in-house quality inspection function to create a superior quality system, and we are working daily to enhance and strengthen our inspection equipment. We have expanded the inspection laboratory and introduced the latest inspection equipment, making it possible to significantly improve quality inspection. In addition, we actively support subcontractors’ factories by providing technical guidance and introducing large-scale production equipment and processing equipment, expanding the range of in-house developed technologies, and promoting the creation of a system that can flexibly respond to user needs.

In 2000, we received the “VM Promotion Award”, which was the first time for a company in the Chubu region in Japan to receive this award for its thorough elimination of waste and high awareness of environmental issues. In addition, in 2001, it led to simultaneous acquisition of “Environmental Management System ISO14001” and “Quality Management System ISO9001” certification. We are seeing visible results, such as high delivery rates. Our overseas factories in Thailand, China, and Indonesia have obtained ISO14001 and ISO9001 as well as IATF16949 certifications.

INNOVATION

Continuous innovation

Since its founding in 1946, Yahata Neji has adopted the mission statement of “opening up new technologies and new fields with a spirit of SanPouZen”. Our customers, business partners, society and our company work well, and create a stable business environment. Based on the idea of ”SoKyakuJin”, looking ahead to the present and the future, we constantly review and verify what end users want and whether we are able to provide the products that customers want, and improve the efficiency of our operations. We are working on innovation for efficiency and rationalization.

Home center DIY business, providing products that look ahead of the times.

A screw that you often see in the DIY section of a home improvement center. Yahata Neji was the first company in Japan to market its screws in packages that were classified by shape and size according to the quantity required by the final user. In 1975, when we started commercialization, screws with low unit prices were basically mass-sold, and it was unthinkable in terms of cost to pack them in bags and sell them in small quantities. However, we got a hint from retail stores in America, where home improvement stores were commonplace, and started working on the business of packaging a large number of small-lot screws.

Packaging screws requires production supply system that sorts accordingly to different shapes and sizes. The sales turnover of screws in stores is fast, and the amount of work involved in production management, quality inspection, classification and sorting by packaging, inventory, shipping, and delivery is enormous works. In order to achieve reliable quality, price and delivery, and to gain the trust of our customers, it was necessary to build a production system and a distribution system based on advanced operation. Since the 1980s, we have been promoting research and development, managing products in real time using computers, and realizing the “Yahata Flow System”, a logistics system developed in-house that combines IT and mechatronics. Since 1995 , thanks to the reliable operation of the “Yahata Flow System”, Yahata Neji received great support from home improvement stores and gained the top market share in the industry. In addition, we have achieved a delivery rate of 100% by repeating numerous kaizen(improvement) and product developments and by thoroughly eliminating waste.

Yahata Neji’s design management has won numerous design awards.

Based on the idea of ”delivering good products with good designs,” we have been working on design management since 1996 to create a brand that expresses the worthiness of Yahata Neji. We worked on realizing a package design that is easy for customers to understand and find, and corporate design activities that express the reliability of our products. We built a design system according to Yahata Neji’s corporate philosophy and operation system focusing on things such as CI(Corporate Identity), packaging, displays, catalogs, websites, and construction materials.This attempt has created a big response both inside and outside the industry. Through various exhibitions, we appealed the world of screws to society as an attractive product, and were highly recognized for adding new value to standardized industrial products. We received design awards in various fields, including the 2002 Good Design Award, Japan Chamber of Commerce and Industry President’s Award, and the 1st Design Excellence Company Award in 2004. We are continuing our efforts to create the “YAHATA Neji Brand” that delivers safeties and trust to our customers

Innovation of self-developed “automation technology”.

In 1995, Yahata Neji completed the “Yahata Flow System,” a logistics system that merged IT and mechatronics. In 2018, it started full-scale operation of the “Yahata Flex System,” a new logistics system for manufacturers. In the field of manufacturing, Japan is currently facing a serious labor shortage, but Yahata Neji has been working on automation technology since the 1990s. In 2000, in order to achieve low-cost production, screw package production was transferred to our Thai factory. After that, we switched to domestic manufacturing because we were able to achieve cost improvements through the establishment of domestic automation technology. Overseas labor costs continue to rise. Yahata Neji’s overseas factories also actively introduce automation technology, aiming to provide a stable product supply and a price that customers can be satisfied with.

Innovation in “product, technology development “ and “new product planning”

“Product planning, development” is essential for the development of a company. YAHATA Neji is working on the development of new product technology for screws through joint research with universities. As a typical product in recent years, we have jointly developed a new locking bolt called “Wedge Lock Bolt”. We will continue to develop new products that are useful to society through basic technology research.

We are also focusing on product planning for end-users of home improvement centers. In addition to screws, we are actively developing DIY specific products that can be used by many people, such as for “disaster prevention”, “storage”, and “gardening” products that are useful in daily life.

Innovation of “Service for Information Age”

We are jointly developing a new ordering system that introduces artificial intelligence (AI), together with a university. Currently, Yahata Neji ships approximately 100,000 of products daily to customers such as major manufacturers and home improvement centers nationwide. In order to further improve accuracy, the introduction of artificial intelligence (AI) is essential. Combining the “Yahata Flow System” and “Yahata Flex System“ enables more subdivided, stable and advanced logistics. One of the objectives is to reduce human work as much as possible to respond to the decrease in the working population and increase the number of people engaged in creative work. For retail stores, we are also working on sign displays and package designs that make it easier to find screws and the development of a product search engine, Neji Quick. We will continue to develop services that satisfy our customers, such as a system that allows customers to instantly search for product information, based on the idea of ”SokyakuJin”.

GLOBAL

“The smooth flow of goods and information” Toward the realization of global optimal production

Respond to the localization needs of customers expanding globally.

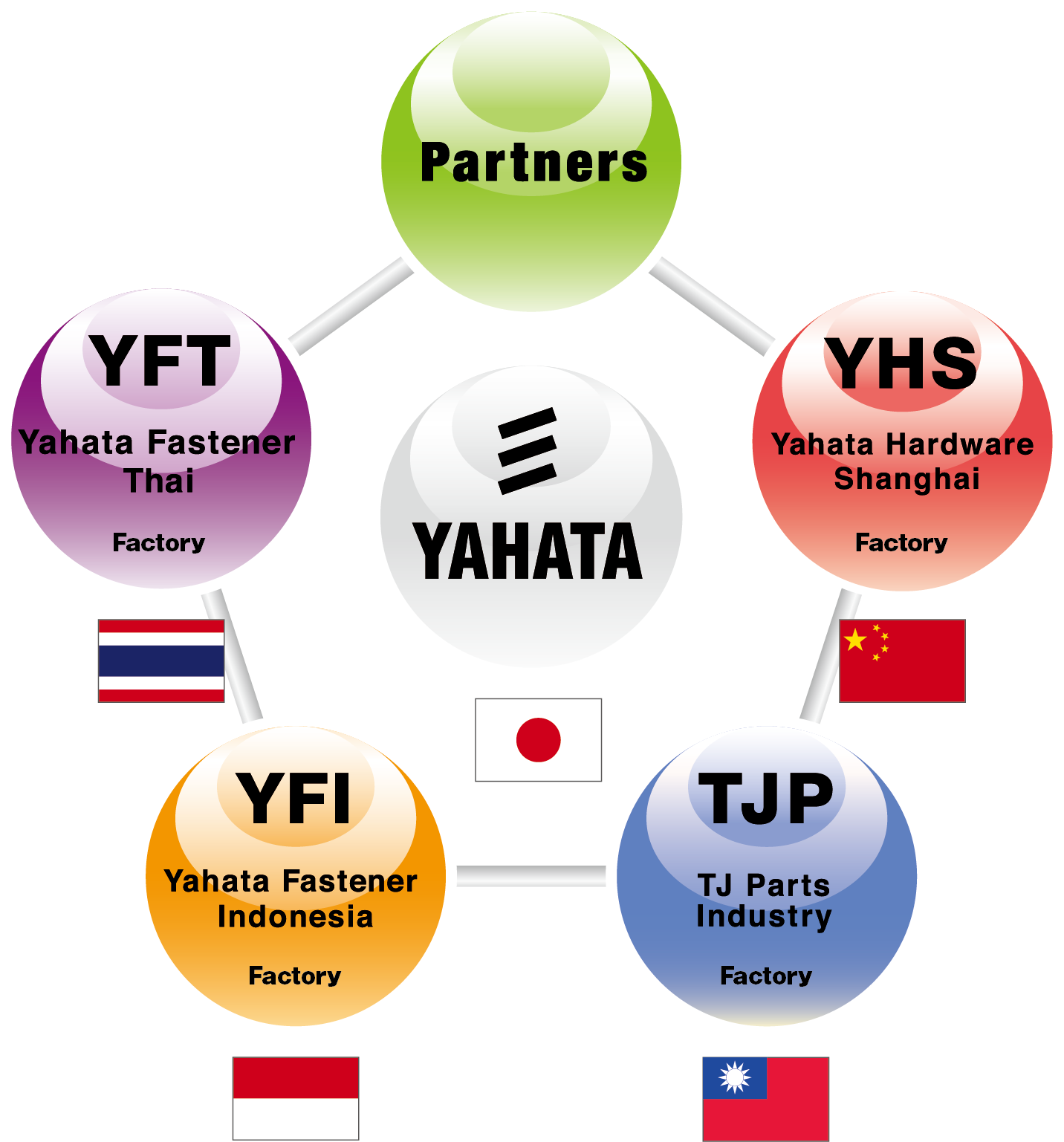

Yahata Neji has expanded its overseas business with the aim of achieving global optimal production.

2000, we established two local subsidiaries for manufacturing and sales in Bangkok, Thailand.

2003, we opened the second overseas manufacturing plant in the suburbs of Shanghai, China.

2011, we opened a manufacturing plant in Jakarta, Indonesia

2013, we opened a manufacturing base in Kaohsiung, Taiwan

We have established five manufacturing bases in Japan, Thailand, China, Indonesia, and Taiwan, and have completed a production and supply systems that can respond to customers’ needs even more quickly and at low cost. Many Japanese companies are expanding outside of Japan that will continue to grow in the future. It is our mission to supply high-quality products to Japanese manufacturing that is expanding overseas.

We will continue to aim for aggressive expansion in the future.

An international procurement system that can meet the high quality standards of our customers

In 1987, YAHATA Neji established the Overseas Business Department in charge of overseas import operations, and has been working to develop its own import routes centered on East Asia, including China, South Korea, Taiwan, and Vietnam. We have built an international procurement system that can meet the high quality standards of our customers. Yahata Neji is involved in all stages from development to manufacturing at overseas production sites, making it possible to sell products that guarantee low cost and high quality. We repeatedly reorganized our organization in line with the changing times. In 2018, we established an independent subsidiary, the overseas trade department as YahataTrading Co., Ltd. In addition to importing from outside of Japan, we are actively working on exporting and selling high-quality Japanese products to countries such as China and South Korea.

Certified as an “Aichi brand” as an excellent manufacturing company.

Recognized for its high level of manufacturing technology, we also manufacture automobile-related parts. Yahata Fastener Thailand (Thailand factory), PT Yahata Fastener Indonesia (Indonesia factory), and Shanghai Yahata Hardware Co., Ltd. (China factory) have acquired IATF16949. Yahata Neji Group’s overseas factories have established a production system that customers can rely on as having Japanese quality. Yahata Neji was certified as receiving the “Aichi Brand” in 2012 as an excellent manufacturing company.